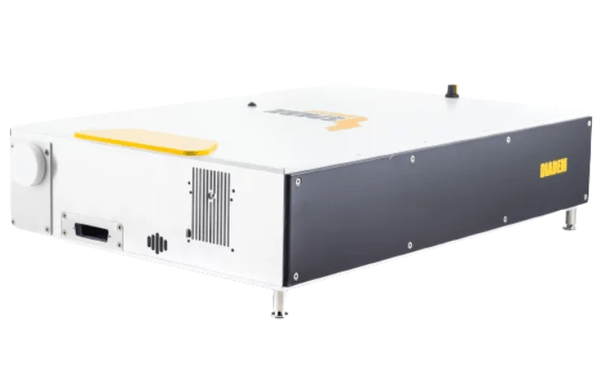

ALCOR 10XX

DPSS Laser, fs Pulsed, 1064 or 1040 nm, up to 4 W, up to 62 nJ, 80 MHz, <130 fs

Key Features:

- 1064nm or 1040 nm (others optional)

- 100 fs to <130fs (depending on configuration)

- Up to 5W

- GDD Precompensation from 0 to -60,000 fs2

- 80MHz rep. rate (others optional)

- Excellent Beam Quality – M2 <1.2 (<1.3 for 920-4W version)

There are many configurations and options available. If you do not see exactly what you need below, please contact us!

POPULAR CONFIGURATIONS:

Picture |

Part Number |

Part Description |

Datasheet |

Price |

Lead Time |

|

|---|---|---|---|---|---|---|

|

ALCOR 1040-2W |

Ultrafast, Femtosecond DPSS Laser, 1040nm, 100fs, 2W, 25 nJ, 80 MHz |

|

10-14 weeks |

Get Quote | |

|

ALCOR 1040-5W |

Ultrafast, Femtosecond DPSS Laser, 1040nm, 110fs, 5W, 62.5 nJ, 80 MHz |

|

10-14 weeks |

Get Quote | |

|

ALCOR 1064-2W |

Ultrafast, Femtosecond DPSS Laser, 1064nm, 100fs, 2W, 25 nJ, 80 MHz |

|

10-14 weeks |

Get Quote | |

|

ALCOR 1064-5W |

Ultrafast, Femtosecond DPSS Laser, 1064nm, 110fs, 5W, 62.5 nJ, 80 MHz |

|

10-14 weeks |

Get Quote |

The ALCOR 1064 femtosecond laser series is specifically designed for biophotonics applications such as multiphoton microscopy. With up to 62nJ of pulse energy (5W @ 80MHz) and >480 kW of peak power, which enables higher brilliance and contrast in two-photon imaging of red fluorophores (RFP) and calcium indicators such as RCaMP, dtTomato and MCherry. In addition, this series can be equipped with the XSight (AOM) module for precise and fast power control, as well as the FLeX Fiber fiber-coupled output module.

The fiber-based design enables a more compact, robust, and reliable laser than its DPSS and Ti:Sapphire counterparts. Through this simplified fiber design, these fiber lasers require little to no maintenance. Historically, researchers have been using Ti: Sapphire lasers, which utilize many more components and moving parts, including water cooling systems, requiring significantly more maintenance and ultimately leading to higher total cost of ownership. The combination of ultra short pulse duration, high repetition rates and high average powers offers many benefits to researchers and OEM microscopy instrumentation manufacturers in the lifesciences and biophotonics fields. In addition, the fiber-based design ensures reliable and robust 24/7 operation, while the ultra-compact, air-cooled user-friendly package eases integration and reduces facility requirements.

To find out more click here to download our white paper on how mode-locked lasers are used in two-photon microscopy.

Why ALCOR:

The ALCOR series of single wavelength 920nm and 1064nm lasers are ideal for those working on multi-photon imaging applications. The combination of high energy (up to 62nJ) and short <130fs pulse width results in the highest peak power available on the market today. This allows the researcher to image deeper into specimens. The additional options available: GDD pre-comp. down to -30,00 fs^2, XSight (AOM) module for fast power control, and fiber coupled output make the ALCOR suitable for all two-photon microscopy setups.

The fiber based design of this series enables a more compact, robust, and reliable laser than its DPSS counterparts while still being air-cooled. Through this simplified fiber design, the ALCOR requires little to no maintenance. Historically, researchers have been using Ti: Sapphire lasers which utilize many more components and moving parts which requires significantly more maintenance ultimately leading to higher total cost of ownership. In the ALCOR, the only consumables are the laser diodes, which are rated for +20,000 hours.

Options:

ALCOR XSight external module:

- Fine power adjustment

- Fast gating with TTL signal (< 1µs response time)

- Fast power modulation with an analog signal (< 1µs response time)

ALCOR FLeX (fiber delivered femtosecond pulses with total pulse control)

- External module for 920nm or 1064nm

- Fine and fast power control (XSight)

- Computer-controlled GDD precompensation from 0 to -30,000 fs^2

- Average power > 0.8 W at the fiber output

Other Options

- Dual – 2 independently controlled laser heads operating at 920 and 1064nm

- GDD Extension – Increase range to -90,000 fs2

- Wavelength – 1035 +/- 5nm

- Repetition Rate – Any fixed frequency from 30MHz to 80MHz

- Frequency Conversion – 460nm (for 920 versions) / 532nm, 266nm (for 1064 versions

| Type | |

|---|---|

| Wavelength (nm) | |

| Output power (W) | |

| Pulse energy (uJ) | |

| Pulse width | |

| Rep rate | |

| Q-switch type |