Micromachining System

The MicroMake Laser Micromachining System from Bright System is an integrated and compact solution designed for high precision and resolution applications. It is currently available at 532nm and 266nm.

The MicroMake Laser Micromachining System from Bright System is an integrated and compact solution designed for high precision and resolution applications. It is currently available at 532nm and 266nm.

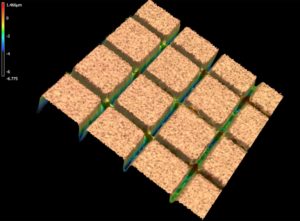

Firstly, the system includes everything for direct laser micro-processing in a single monolithic element. Furthermore, live microscope imaging of the sample is available during all process phases for alignment and immediate quality check.

The MicroMake is perfectly suited for a large variety of materials. For example, it handles materials currently used in the fields of microelectronic circuits, display fabrication and correction, biomedical devices machining, and optical substrates micro processing.

Finally, typical applications of this compact system include controlled ablation, micro drilling, precision cutting, selective removal and direct 3D microfabrication.

Let Us Help

If you have any questions, or if you would like some assistance please contact us here. Furthermore, you can email us at info@rpmcdev.maxdroplet4.maxburst.dev to talk to a knowledgeable Product Manager. Finally, head to our Knowledge Center with our Lasers 101 page, and Blogs, Whitepapers, and FAQ pages for further, in-depth reading.