Bright Solutions develops state-of-the-art diode-pumped solid-state (DPSS) laser systems aimed at superior efficiency, compactness, and reliability for industrial applications. In business for over 20 years, with nearly 10,000 units fielded to date, the experts at Bright Solutions provide a world-class level of quality, customer care, and service.

Continuous Improvement & Application-Specific Customization

Their wealth of knowledge in laser engineering and applications experience has led to the development and continuous improvement of multiple series of high-quality DPSS lasers. The key design features of these various DPSS laser series are geared toward critical application requirements that overlap with our collective laser and applications expertise. We work closely with Bright Solutions and our customers to provide customization to their standard models based on your unique application requirements, so you can get the performance you need to ensure excellent results.

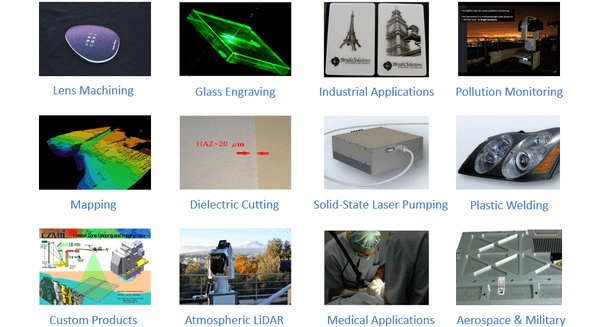

Standard & Custom Solutions for Many Industries

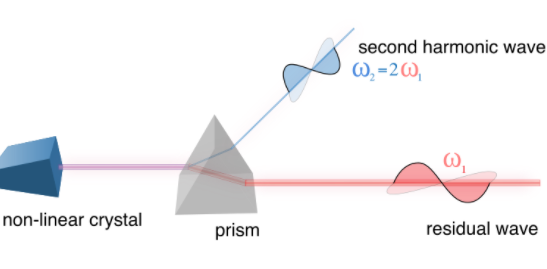

Bright Solutions has developed several standard series of DPSS laser systems with features such as 2nd and 3rd harmonics, fiber or free space outputs, and air or water cooling, including their Wedge, SOL, and ONDA platforms. In addition to their standard laser systems, Bright Solutions engineering group has developed a wide range of custom nanosecond and sub-nanosecond DPSS lasers for various applications requested by our customers from the aerospace, industrial and medical communities.

Custom products typically include:

- High Power/Energy ns and sub-ns MOPA Lasers, UV, Visible and IR

- Optical Parametric Converters

- Amplified Single-Frequency sub-ns lasers

- Amplified Picosecond Lasers

- DPSS Femtosecond Laser at 1um

Experience with Many Applications & Materials

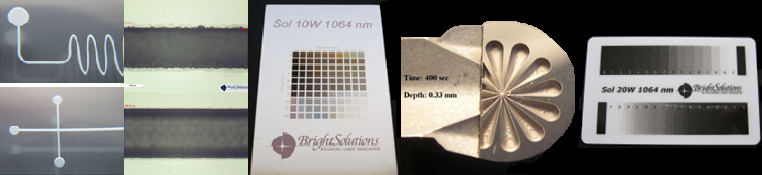

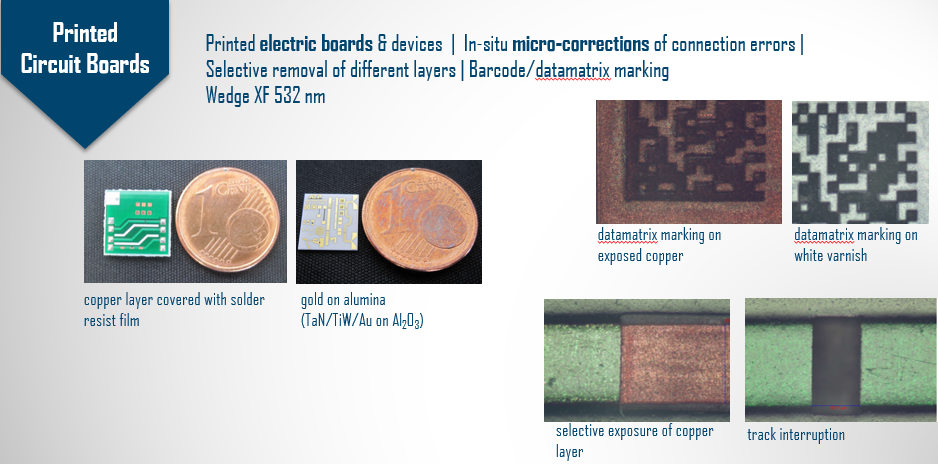

In their modern applications lab, ideal for proof-of-concept testing and sample processing, they provide a host of DPSS laser configurations with a range of wavelengths and power levels. Their dedicated staff has years of application experience and offer process development support to help get your project up and running. The experience of the applications lab experts covers a broad range of materials and processing techniques. For example, with glass and sapphire, they have demonstrated lens marking, surface engraving, microchannel processing, dicing, hole drilling, and intra-volume marking. They can perform color marking on stainless steel, deep 3D laser milling on synthetic polycrystalline diamond (PCD), micro-hole drilling through nickel iron alloy, gray scale marking on plastics, high contrast marking on heat-sensitive polymeric materials, and many other successful application examples. Below, we’ve laid out a couple successful application examples, provided by Bright Solutions, along with recent articles we’ve written on these applications. Click one of the links below to see a presentation detailing their applications and laser experience or to see the full list of standard options available from Bright Solutions.

Check out this previous article: “Expert Solutions for Your PCB Processing Applications”

Another related article: “ID Card Marking – How Does Pulse Energy Modulation Affect Mark Quality?”

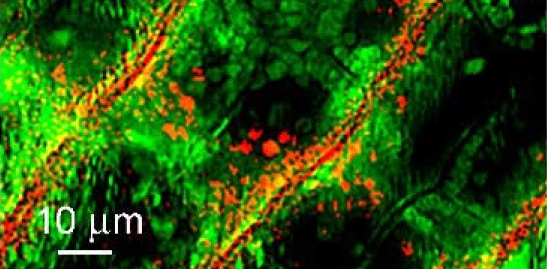

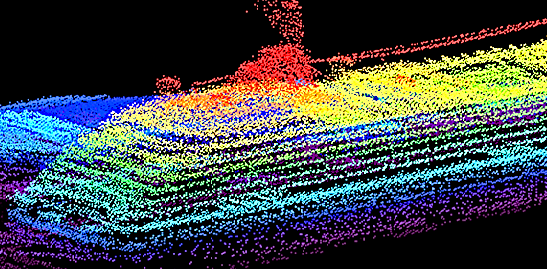

Check out a couple other recent articles discussing other applications, utilizing Bright Solutions DPSS Lasers: Raman Spectroscopy, LIDAR & Bathymetry, and Harmonic Generation.

| Raman Spectroscopy: Why Are Picosecond Pulses Superior to Femtosecond? | Key Laser Requirements for Bathymetric and Topographic LIDAR | High-Energy Q-Switched Lasers for Harmonic Generation |

|

|

|

Talk to a knowledgeable Product Manager today by Contacting Us here, or by emailing us at info@rpmcdev.maxdroplet4.maxburst.dev!