MatchBox Combiner

Laser Diode Multi-Wavelength Combiner

Key Features:

- 2 to 4 individually controllable laser diode drivers

- Ultra-compact All-in-One design

- USB powered

- Perfect for handheld/portable devices

- Thermally stabilized optics

- Monolithic design for hands-free operation

- Fiber coupling and beam shaping options

- Automatic current control

- QC3.0 compatible USB-C power input (in breakout box)

POPULAR CONFIGURATIONS:

Picture |

Part Number |

Part Description |

Datasheet |

Price |

Lead Time |

Quantity |

|

|---|---|---|---|---|---|---|---|

|

40A-52A-64A-78A-16-DM-NT |

Laser Combiner: 405 nm, 520 nm, 638 nm, 785 nm, Options included: Direct TTL, Clean-up filter, Remote PC control, SMA Port |

$11,005.00 | Get Quote | |||

|

40A-52A-64A-78A-11-DM-CF |

Laser Combiner: 405nm, 520nm, 638nm, 785nm, Options included: Direct TTL, Clean-up filter, Remote PC control, Free-space |

$7,155.00 | Get Quote | |||

|

40A-48A-64A-XXY-15-DM-PT |

Laser Combiner: 405 nm, 488 nm, 638 nm, Options included: Direct TTL, Clean-up filter, Remote PC control, Polarization Maintaining |

$11,775.00 | Get Quote | |||

|

52A-78A-XXY-XXY-16-DM-NT |

Laser Combiner: 520nm (80mW), 785nm (150mW) Options included: Direct TTL, Clean-up filter, Remote PC control, SMA Port |

$6,715.00 | Get Quote | |||

|

40A-45A-52A-64A-11-DM-CF |

Laser Combiner: 405nm (120mW), 450nm (70mW), 520nm (80mW), 638nm (130mW) Options included: Direct TTL, Clean-up filter, Remote PC control, Free-space |

|

$7,155.00 |

10-14 weeks |

Get Quote | |

|

40A-48A-52A-XXY-11-DM-CF |

Laser Combiner: 405nm (120mW), 488nm (40mW), 520nm (80mW) Options included: Direct TTL, Clean-up filter, Remote PC control, Free-space |

|

$5,120.00 |

10-14 weeks |

Get Quote | |

|

40A-48A-52A-64A-13-DM-PT |

Laser Combiner: 405nm (50mW), 488nm (20mW), 520nm (40mW), 638nm (50mW) Options included: Direct TTL, Clean-up filter, Remote PC control, Single-mode Fiber |

|

$11,775.00 |

10-14 weeks |

Get Quote | |

|

52A-78A-XXY-XXY-11-DM-CF |

Laser Combiner: 405 nm, 520 nm, 638 nm, 785 nm, Options included: Direct TTL, Clean-up filter, Remote PC control, Free-space |

|

$4,955.00 | Get Quote | ||

|

40A-45A-52A-64A-14-DM-PT |

Laser Combiner: 405nm (100mW), 450nm (50mW), 520nm (70mW), 638nm (100mW) Options included: Direct TTL, Clean-up filter, Remote PC control, Multimode Fiber |

|

$7,815.00 |

10-14 weeks |

Get Quote | |

|

XXY-40A-52A-64A-13-DM-PT |

Laser Combiner: 520 nm, 785 nm, Options included: Direct TTL, Clean-up filter, Remote PC control, Single-mode Fiber |

|

$11,225.00 | Get Quote | ||

|

40A-48A-52A-XXY-14-DM-PT |

Laser Combiner: 405nm (100mW), 488nm (40mW), 520nm (70mW) Options included: Direct TTL, Clean-up filter, Remote PC control, Multimode Fiber |

|

$6,715.00 |

10-14 weeks |

Get Quote | |

|

40A-48A-52A-64A-15-DM-PT |

Laser Combiner: 405nm (50mW), 488nm (20mW), 520nm (40mW), 638nm (50mW) Options included: Direct TTL, Clean-up filter, Remote PC control, Polarization Maintaining |

|

$13,975.00 |

10-14 weeks |

Get Quote | |

|

40A-48A-52A-64A-16-DM-NT |

Laser Combiner: 405nm (100mW), 488nm (40mW), 520nm (70mW), 638nm (100mW) Options included: Direct TTL, Clean-up filter, Remote PC control, SMA Port |

|

$7,815.00 |

10-14 weeks |

Get Quote |

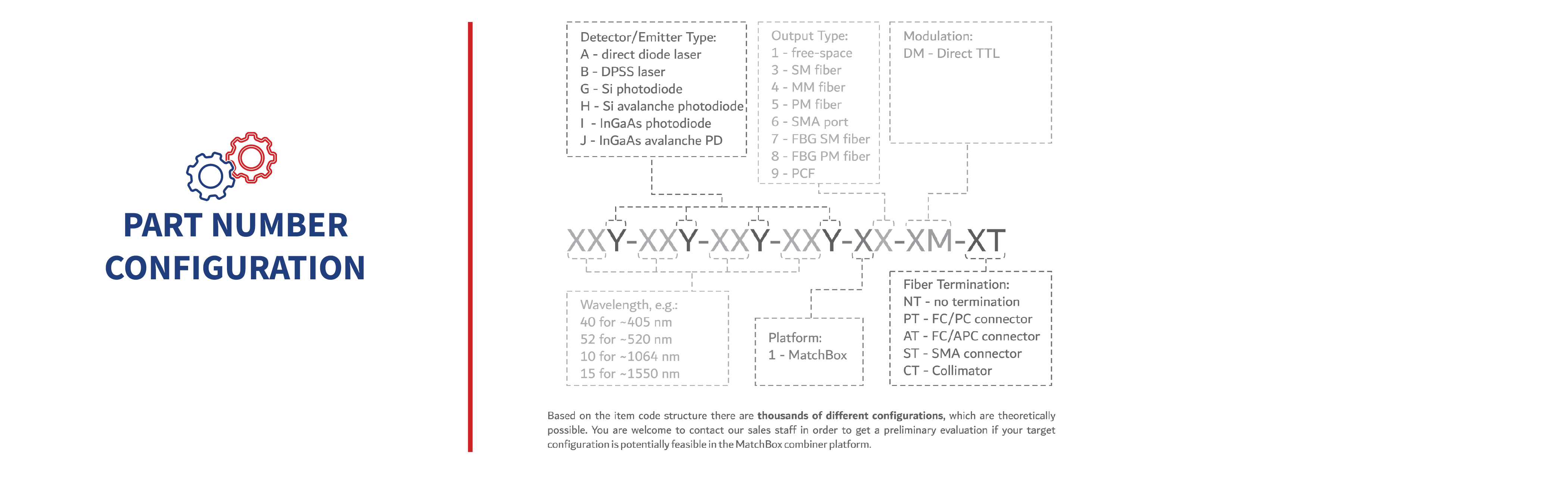

The MatchBox Multi-Wavelength Laser Diode Combiner series is a configurable, ultra-compact, turn-key, multicolor laser system. It utilizes a classical dichroic combining technique to combine four channels for laser diodes or photodetectors into a single optical path. The package includes two to four laser diode drivers, TEC driving electronics, a microprocessor, and the precision-aligned electro-optical part, all inside the world’s smallest footprint of 30x50x18 mm. As a result, the laser/detector unit provides unprecedented compactness and functionality. The unit is designed as an integration-ready electro-optics unit, which can be connected to a control mainboard and power supply of an instrument, perfect for OEM and portable/handheld devices and applications.

This flexible series of MatchBox Multi-Wavelength Laser Diode Combiners has many wavelength options from 405nm to 1064nm, allowing you to choose the precise combination to suit your application. It also has options including free-space, SM, PM, and MM fiber-coupled output, and a few heat sink options to choose from. Numerous customization options allow you to choose the configuration that exactly suits your needs, including customer specified dichroic mirrors, clean-up and blocking filters, beam shaping optics, pre-programmed modulation patterns, and more! The second generation MatchBox Multi-Wavelength Combiners come with a redesigned Break-out-Box and completely revamped control software, increasing functionality and ease of use, allowing for individual control of each wavelength.

A newly implemented, automated robotics assembly facility ensures scalability of manufacturing, complete process control, increased quality and repeatability, fast adaptation to customer needs, and optimized throughput to keep up with customer demand and implement a number of “in stock lasers.”

| Type | |

|---|---|

| Wavelength (nm) | |

| Output power (W) | |

| Mode | |

| Output |